What is Thermal Desorption?

Thermal Desorption is a method used to introduce samples into a Gas Chromatography-Mass Spectrometry (GC-MS) system. In this technique, target compounds are either collected on a sorbent material, concentrated on an extraction device such as a GERSTEL Twister®, or directly released from the sample itself. Heat and inert gas flow are used to transfer the compounds to a trap, which focusses and rapidly injects them onto the GC column. This procedure enhances chromatographic separation and allows for extremely low detection limits.

Why TD?

The thermal desorption process is the most efficient way to determine volatile and semi-volatile compounds (VOCs and SVOCs) in air. These compounds can be captured at concentration levels thousands of times higher than in the original air. Most compounds are stable and tightly enough bound to the sorbent, so sampling can be done remotely with no special precautions needed to transport samples to a laboratory for analysis.

GERSTEL TDU with Multiple Tubes from GERSTEL, Inc. on Vimeo.

TD is not limited to gas samples though. Compounds can be thermally extracted directly from a wide range of solid samples, such as plastics used in automobile parts, beverage bottles, or electronic components or more porous materials such as paper, cloth, and carpet. These thermally extracted compounds can help to determine the cause of off-odors or flavors, electronic system failure or with a forensic problem.

Analytes can also be extracted from liquids either by selective evaporation of the liquid matrix, followed by thermal extraction of the analytes from the resulting matrix or by using a water compatible sorbent to extract analytes from a liquid followed by thermal desorption of the sorbent. The most used example of this is stir bar sorptive extraction (SBSE) sold as the GERSTEL Twister®

In all cases, TD serves as very efficient and versatile way to capture and concentrate trace amounts of compounds found in solids, liquids, and gases.

How does TD work?

The sample is collected by passing air through a tube containing the sorbent, once sampling is complete, the tube is placed in the thermal desorber either manually or by a multifunctional robotic autosampler. The thermal desorber is then sealed and heat and gas flow are applied to gently desorb the compounds from the sorbent.

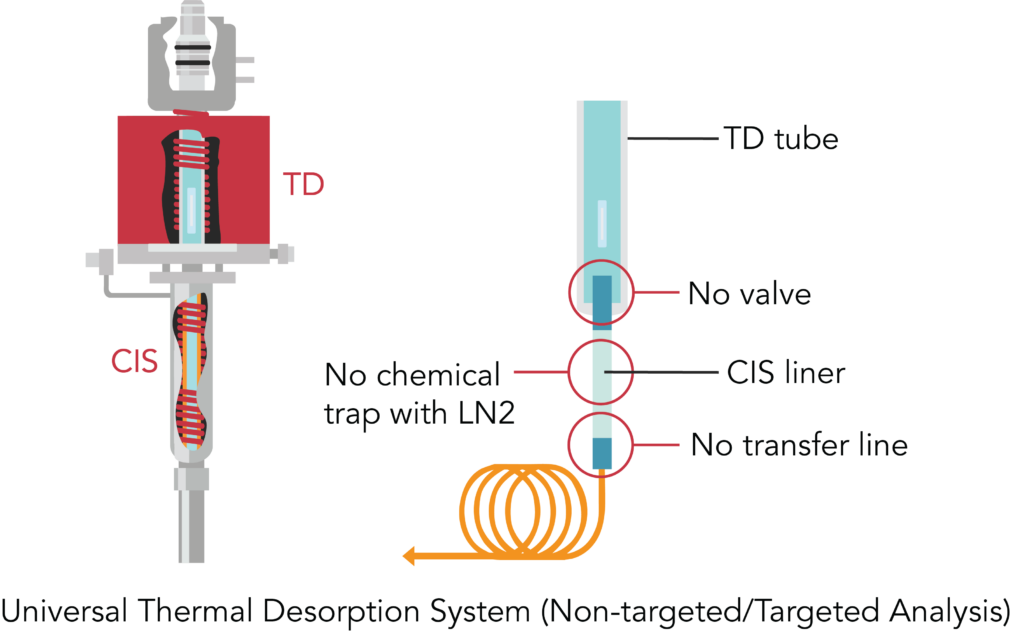

The released compounds pass directly into a focusing trap placed just below the tube. This transfer can occur with a split flow (to prevent column overload) or without a split flow (to achieve lowest detection limits). The focusing trap can be held at a low temperature to trap compounds on an inert surface (such as glass beads or quartz wool) or at higher temperatures using additional sorbents. Trapping at low temperature is preferred since all compounds are trapped and there is no doubt that any compounds crucial to the analysis are missed. Using sorbents in the focusing trap is acceptable when the analytes to be determined are known (targeted analysis) and standards are available to ensure proper trapping and transfer to the GC column is occurring.

After the compounds has been trapped, the focusing trap is rapidly heated and analytes are passed directly onto the GC column for separation followed by detection with a mass spectrometer. As with the transfer from the thermal desorber, transfer can be performed in a split or splitless mode to further dilute or concentrate the analytes before they reach the GC column.

TD done this way has many practical benefits:

TD done this way has many practical benefits:

- The direct to trap – direct to column design eliminates the need for valves and transfer lines providing the most direct inert path for the analytes to pass through the system. This eliminates sample loss and carry over as well as reducing maintenance costs.

- Trapping can be done non-selectively at low temperatures for determination of unknowns (non-targeted analysis) or the trap can use sorbents for method specified compound determination (targeted analysis).

- Split flow in the system is multiplicative: using a 100:1 split at each stage results in an overall reduction of signal by 10000:1. Alternatively, both stages can be splitless. In this way the dynamic range of the instrument is maximized, allowing for the analysis of very dilute or very concentrated samples.

- As mentioned above, almost any type of sample is amenable to TD: solids, liquids, and gases. This flexibility maximizes the use and investment with a single system being able satisfy a wide range of analytical needs.

- The use of a robotic autosampler adds to the systems utility, allowing sample preparation for thermal desorption to be performed without human intervention, and providing access to techniques beyond TD (such as dynamic headspace, Twister, TF-SPME, and pyrolysis).

What is TD used for?

TD is used in many different applications. Some common examples are:

- The analysis of flavors and fragrances used in foods and consumer products

- Measuring off-gassing of materials used in homes, offices, and cars (the ‘new car smell’)

- Examining foods directly for authenticity or for understanding flavor or odor complaints

- Detecting dangerous chemicals for law enforcement or military applications

- Determining the quality of indoor or outdoor air, and making sure they meet legal requirements

- Making sure that packaging for drugs or plastics in medical implants are safe