The Multipurpose (MPS) Robotic Smart Series autosampler, when correctly configured, has a precision of within 0.1 mm, but this relies on the proper calibration of tools and teaching of modules. When a new tool is added to the system, it will require calibration, which entails teaching it to the reference point of the system.

The reference point is a small black bullseye located somewhere on the system – on systems with manual tool exchange, it is usually located at the end of the tray holder. On MPS roboticpro systems, the reference point is at the end of the tool exchange station. By teaching a new tool to this reference point, the system can adjust for any small differences in the tool, making sure that it will be able to access all other parts of the system.

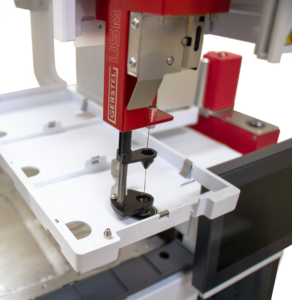

Some tools require additional steps in calibration – in the case of SPME tools, the calibration procedure sets the Fiber Alignment and Standby Position Offset values, which are critically important to both the longevity of fiber, and to the adsorption of the sample material onto fiber. This should be done each time a new fiber is installed, to account for any manufacturing deviations in length. Whenever a new tool is added to the system, it must be calibrated before it can be used.

Contact service@gerstelus.com for details or download the MPS familiarization guide from our Online Store.