Chemistry Drives Flavor in Foods and Beverages

Consider what your favorite food or beverage may be… now ask yourself, “Why is it that I love it so much?” Aside from the price, sustainable ingredients, and nutrition facts, flavor is a top driver for consumers. Flavor is driven by chemistry, which makes analyzing the complex interplay of important volatile organic compounds (VOCs) and sensory-active compounds a challenge for the food and beverage industries.

Consider what your favorite food or beverage may be… now ask yourself, “Why is it that I love it so much?” Aside from the price, sustainable ingredients, and nutrition facts, flavor is a top driver for consumers. Flavor is driven by chemistry, which makes analyzing the complex interplay of important volatile organic compounds (VOCs) and sensory-active compounds a challenge for the food and beverage industries.

Even the slightest change in VOCs can alter the way a product is perceived and will ultimately affect the consumer experience. Capturing and quantifying these small but potent differences requires a highly effective sample extraction and introduction technique that promotes reliable detection and identification.

The Role of MIB and Geosmin in Whiskey

Among the VOCs that shape product integrity, two stand out for their powerful influence in whiskey products: 2-methylisoborneol (MIB) and geosmin. Even at trace levels, these compounds are well known for imparting earthy, musty, potting soil, and beet-like off notes that can dramatically alter how a finished whiskey is perceived. Both are detectable by the average person at levels as low as 1-10 ppt in water, meaning even a small amount can interfere with a consumer’s drinking experience.

The caveat with these compounds is that they enter the whiskey before it is bottled and even before it is aged in a barrel. They often originate from the grain, water sources, and storage conditions.

GERSTEL has demonstrated an effective approach for extracting and quantifying MIB and geosmin from grain (AppNote 288) and finished whiskey products (AppNote 276), providing distillers, specifically, with powerful tools to maintain product integrity throughout production.

Where It Begins: MIB and Geosmin at the Source

Whiskey is made from mash bills of one or more grain varieties, typically any combination of corn, rye, barley, or wheat. Good products start with good ingredients, but quality is sacrificed when MIB- and geosmin-contaminated water sources infiltrate the grains via irrigation, processing, and storage conditions. Before whiskey is even made, flavor integrity and product acceptance are heavily influenced by what happens at the grain level. Furthermore, these grains are also used to make bread, pasta, and cereal, thus extending the influence of MIB and geosmin to more than just whiskey.

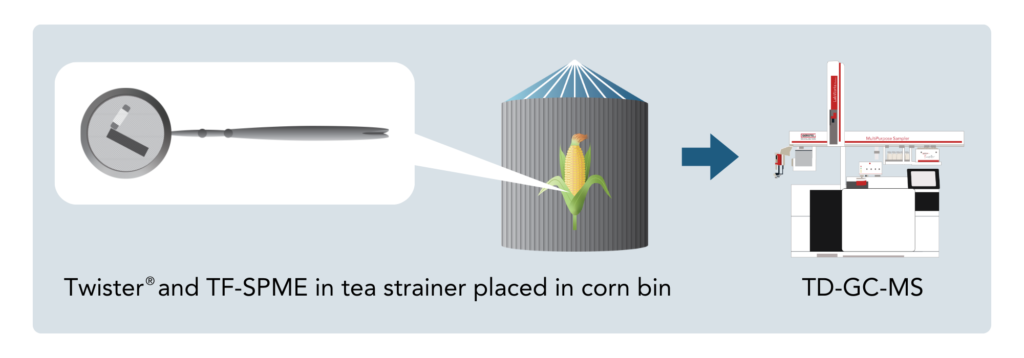

GERSTEL, Inc. collaborated with the University of Kentucky James B. Beam Institute and the USDA’s Agricultural Research Service group to develop a practical and effective method for extracting MIB and geosmin from corn bins.

Sample Preparation and Extraction

Several GERSTEL Twister® stir bars and TF-SPME membranes were prepared in metal tea strainers to create a rugged sampling device. The devices were shipped to the University of Kentucky. Each apparatus was secured to a string and suspended in individual corn bins for four hours for passive extraction of VOCs, specifically targeting MIB and geosmin. After exposure, the stir bars and membranes were sealed and shipped back to GERSTEL, Inc. for analysis by thermal desorption–gas chromatography–mass spectrometry (TD-GC-MS). This solventless approach ensured high recovery and transport stability. At the same time, the large sorptive phase of the Twister stir bars and TF-SPME membranes provided enhanced capacity compared to traditional SPME fibers.

Differences in Corn Bins

MIB and geosmin were quantified by preparing five-point external calibration curves of MIB and geosmin standards with their respective deuterated internal standards. Ions 168 and 171 m/z for geosmin and geosmin-d3, and 112 and 115 m/z for MIB and MIB-d3 were used for quantitation.

The study revealed clear differences in geosmin content depending on storage conditions. In one bin (Bin #3), a small pinhole water leak resulted in elevated microbial activity and increased MIB and geosmin production. When all grain remained in Bin #3, geosmin levels averaged 122.8 ng. After approximately a third of the grain was removed, geosmin levels dropped substantially to 28.4 ng, demonstrating the strong influence of moisture infiltration and storage conditions on the initial ingredients.

On the other hand, MIB could not be accurately quantified with TD-GC-MS alone. Across all the corn bins, the amount of MIB remained unchanged, averaging about 25.0-30.0 ng. This is because, unlike geosmin, MIB often coelutes with competing VOCs in sample matrices, and because its ions are not unique, it cannot be accurately measured without additional means of separation. This challenge has been addressed in finished whiskey.

Where Consumers Notice: MIB and Geosmin in the Bottle

the Bottle

While grain is the starting point, consumer satisfaction ultimately comes from the experience at the bottle. MIB and geosmin often survive fermentation, distillation, and aging steps and can even be intensified by these processes. To demonstrate and quantify the impact of both compounds in finished whiskey, GERSTEL, Inc. developed a methodology to extract MIB and geosmin from different whiskey products. Additionally, GERSTEL has developed a reliable means of improving the separation of MIB from other matrix components using a Selectable 1D/2D-Gas Chromatography-Mass Spectrometry instrument (1D/2D-GC-MS) to allow for accurate quantitation.

Sample Preparation and Extraction

Five whiskey products were obtained from a local liquor store. Each was diluted to 1% ethanol in water for a total volume of 10 mL. Each sample was saturated with NaCl and then gently heated at 65 °C for 3 minutes, followed by SPME for 30 minutes. The SPME fiber was desorbed in splitless mode on three different instruments:

1. GC-MSD using SIM mode

2. GC-Triple Quadrupole (GC-TQ) using multiple reaction monitoring (MRM) mode

3. 1D/2D-GC-MS using SIM mode

1D/2D-GC-MS Wins

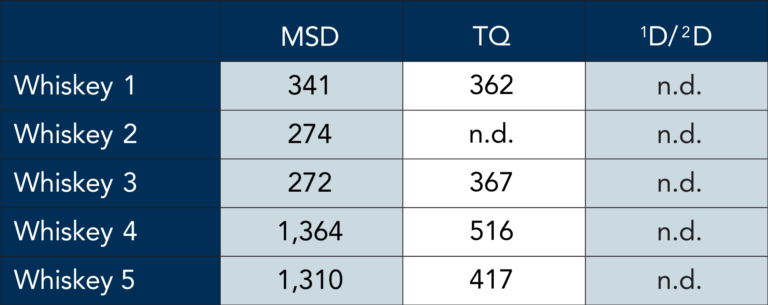

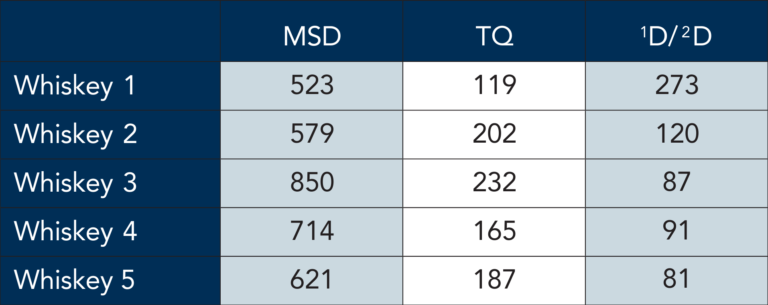

To accurately quantify MIB and geosmin, separate five-point matrix calibration curves were prepared from 5-100 ppt and extracted using SPME. The resulting concentration of MIB and geosmin in each whiskey sample was measured on the three instruments.

From these results, it can be concluded that single dimension GC separation suffers from ion interferences from coeluting compounds even with the GC-TQ in MRM mode. Hence, this is why MIB was detected using GC-MSD and GC-TQ, but not 1D/2D-GC-MS. The 1D/2D-GC-MS overcomes challenges with coeluting compounds by employing two columns with orthogonal stationary phases. In doing so, MIB and geosmin were successfully separated from interfering analytes in the whiskey matrix, and their concentrations were reported with greater accuracy.

AppNote 276 further demonstrated that Twister extraction provides higher analyte capacity than SPME and avoids competition effects in ethanol-rich matrices, making it the preferred technique for reliable quantitation in finished whiskey.

Beyond MIB and Geosmin

While MIB and geosmin serve as striking examples of how trace-level compounds can alter a product, they represent only a fraction of the challenges faced by the food and beverage industry. From monitoring freshness and shelf stability to detecting off-notes and contaminants, the same sensitive, solventless TD-GC-MS GERSTEL workflows applied here extend across countless products and processes. By combining robust field sampling, high-capacity extraction, and advanced separation techniques, such as 1D/2D-GC-MS, GERSTEL enables the industry to ensure consistency and protect consumer satisfaction. Furthermore, when paired with GERSTEL’s Olfactory Detection Port (ODP 4), these workflows can be strengthened by linking mass spectral data directly to sensory-active compounds of interest.